SKM Jigheads

One of the difficulties in designing a jig head mould is the hook size,

hooks as well as other items of tackle, swivels being a prime example

vary vastly in size and shape from one supplier to another even

though they may well be listed as the same size

For Jig hooks let’s say a 6/0 size the factors that may change are

· the actual overall length of the hook,

· the gape (or gap) of the hook (distance from point to shank)

· the length of the eye stand-up.

· the angle of the eye stand-up

· varying hook curves

And all these in the same hook classed as a 6/0

Since a prime factor in the moulding of a jighead is a good fitting of

the hook then supplies of identical hooks could become an important

factor or a stopper if supplies cannot be found to suit the mould.

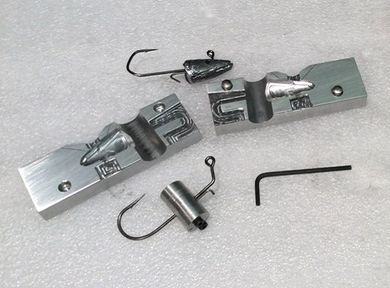

The SKM Jighead mould goes a long way to alleviating this problem

by featuring a hook loader cassette.

This mould/cassette system enables hooks of different sizes to be used with one mould, for example the 32g jighead mould can be used with most hooks from 4/0 up to 7/0, with anything from 45 degree eye bends to 90 degree eye bends.

This is achieved by allowing the hook to move right or left in the cassette and allowing the cassette to move up and down in the mould giving the perfect fit to any size or shape of jig hook.

The hook loader cassette also produces the concave curve behind the head which would normally be impossible to cast.

As a final bonus, the hook loader cassette also holds the wire retaining clip (that holds the jelly/plastic body) in place throughout the casting process.

This is achieved by allowing the hook to move right or left in the cassette and allowing the cassette to move up and down in the mould giving the perfect fit to any size or shape of jig hook.

The hook loader cassette also produces the concave curve behind the head which would normally be impossible to cast.

As a final bonus, the hook loader cassette also holds the wire retaining clip (that holds the jelly/plastic body) in place throughout the casting process.

Loading the Cassette......

Firstly choose your hook and check that there is actually a position in which it fits in the mould. (or try another hook, but most will fit)

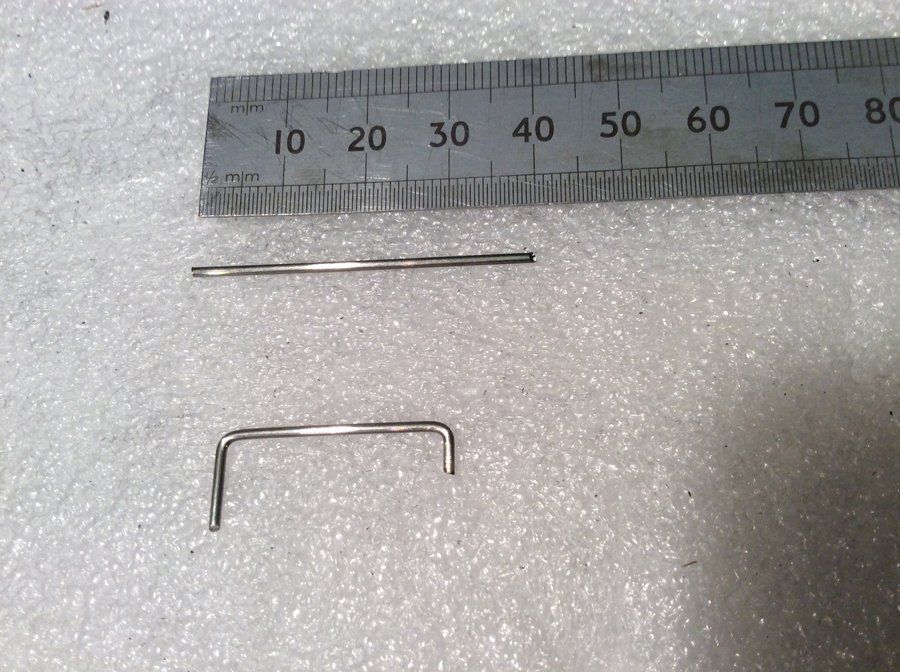

The retaining clip is made from a standard gripwire (1.2mm Diameter). Cut to approx 40mm long and make a bend at one end 90 degrees by approx 2mm, make a bend at the other end (in the same direction) 90 degrees by approx 5mm)

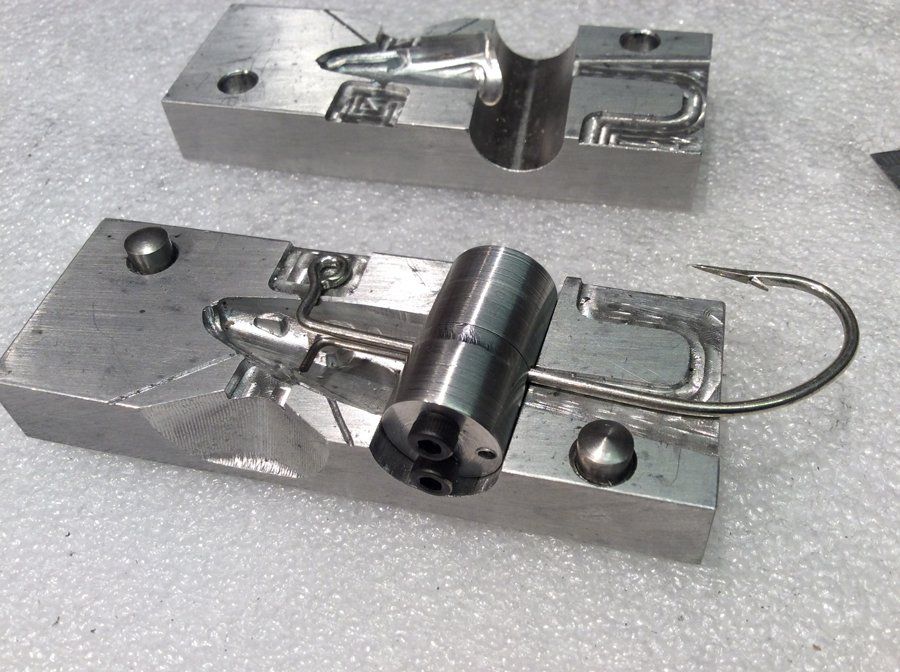

undo the screws in the cassette and pull apart.

bent as shown,fit the clip into the lower half of the cassette by allowing the 90 degree bend (the longest bend) fit into the hole. (the lower half is the half with the two through holes)

You may find it advantageous to fill this hole with a little blue tack before starting your jig making session as this nicely holds everything in place.

Then fit the hook itself above the wire clip with the eye pointing the same way as the extended piece of wire clip, this end of the wire is the retainingend that casts into the lead.

The retaining clip is made from a standard gripwire (1.2mm Diameter). Cut to approx 40mm long and make a bend at one end 90 degrees by approx 2mm, make a bend at the other end (in the same direction) 90 degrees by approx 5mm)

undo the screws in the cassette and pull apart.

bent as shown,fit the clip into the lower half of the cassette by allowing the 90 degree bend (the longest bend) fit into the hole. (the lower half is the half with the two through holes)

You may find it advantageous to fill this hole with a little blue tack before starting your jig making session as this nicely holds everything in place.

Then fit the hook itself above the wire clip with the eye pointing the same way as the extended piece of wire clip, this end of the wire is the retainingend that casts into the lead.

Now Slide the top half of the cassette over this assembly and turn until the slot sits nicely over the hook

Hold in this position and fit the 2 screws.

These need only to be tightened by hand but must close the cassette completely all around. Feel free to use an allen key if you wish.

At this point the hook should be able to slide right and left easily in the cassette.

Fit the cassette to the mould and slide the hook right or left until the eye aligns with the groove and then slide the cassette up and down in the mould till the eye has the required protrusion out from the head.

Fit the second half of mould, clamp and cast.

Hold in this position and fit the 2 screws.

These need only to be tightened by hand but must close the cassette completely all around. Feel free to use an allen key if you wish.

At this point the hook should be able to slide right and left easily in the cassette.

Fit the cassette to the mould and slide the hook right or left until the eye aligns with the groove and then slide the cassette up and down in the mould till the eye has the required protrusion out from the head.

Fit the second half of mould, clamp and cast.

After casting, unclamp and disassemble the mould

Remove the jighead from the mould then remove the cassette from the hook,

Remove the jighead from the mould then remove the cassette from the hook,

with a pair of pointed nose pliers slightly twist the end of the retaining clip to about 120 degrees so that it is pointing forward and snip to length if required

You should now have a perfectly cast jighead with your desired hook which has a realistic look and a concave rear of the head to make the gills look extended and to help hold the body in place.

Decoration and eyes are to be fit at this point if so desired or simply left as it.

These Moulds are currently available in 32g size as shown above but soon to be scaled

to whatever size is required up to about 60g